|

|

Multimine Scheduler Essentials |

Multimine Scheduler Essentials

Multimine Scheduler (MMS) works exactly like Studio NPVS except that some operations apply to all mines, some to specific mines and some have different outcomes for all mines and for specific mines.

|

|

You can launch a Multimine (.mms) project directly from Windows Explorer by double clicking its icon. The launched system will 'know' that a multiple-mine project is open. |

This topic contains the following sections:

- Multimine functions

- Mine-specific functions

- Multimine key functions

- Functions sensitive to mine selection

- Functions executed independently of mine selection

- Importing geological models into a Multimine project

- Deleting mines from a Multimine project

- Generating economic models in a Multimine project

- Pit optimization in a Multimine project

- Multimine pushback generation

- Multimine scheduling

- Multimine MAO (Material Allocation Optimizer)

- Multimine MFO (Mine Flow Optimizer)

- Multimine capital costs

- Multimine haulage analysis

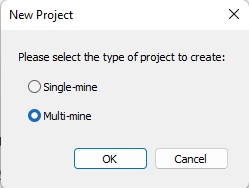

You choose to create a single or multimine project as the first point of project creation:

Selecting Multi-mine

configures your project for multiple mine functions. the Optimization ribbon's Multimine

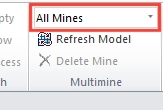

group is activated with the default [All Mines] entry selected:

You can swap to any available mines where the corresponding block

model has been imported into the project. The outcome of many,

but not all, MMS commands depends on the mine selected in this

list. This command group is disabled for single mine projects.

The outcome of each operation listed below depends on the select

mine; some commands are disabled when [All Mines] entry is selected

as they must apply to a particular mine. For example, if the list

box displays [Lonecone] and you choose an Import

Surface command (using the Optimization

control bar or ribbon commands), the surface will be imported

and be used in conjunction only with the Lonecone

model.

-

Import, export and visualize surfaces.

-

Import, export and visualize boundaries.

-

Export and visualize block models including MAO/MFO result model.

-

Digitize region boundaries.

-

Define economic settings and pushbacks settings.

-

Verify economic model validity (Check Values).

-

Copy settings (economic, pit optimization, pushbacks and scheduler) to active MMS document from NPVS document or another MMS document.

-

Copy boundaries active MMS document from NPVS document or another MMS document.

-

Define and visualize 3D slope regions.

-

Check accuracy of pit slopes modeling (Check Slopes).

-

Define pushback input file, haulage destinations and capital costs for the Scheduler.

-

Update economic settings for MAO/MFO.

-

Edit surface files (Combine Files).

-

Divide a pit into two smaller ones (Partition Pit).

Functions sensitive to mine selection

-

Run Economic Model to generate models for all mines or just for the selected mine.

-

Report Options: choose options for all mines reports or for particular mine reports. You should define all options; the options for all mines are usually different from options for a particular mine.

-

Report Reserves: generate reserve report for a selected mine or for all mines, which in this case is a collection of mine specific reports.

-

Pit Optimization Settings: all mines settings define time, discount rate and sequencing parameters; mine specific settings relate to ultimate pit, slopes and other options. You must define all settings before running pit optimization.

Functions executed independently of mine selection

The remaining MMS operations are run independently of the mine dropdown list selection. This includes all principal optimization programs, from Pit Optimizer all the way through to MAO/MFO (which always run in the all mines mode), and some supporting operations like copying surfaces between documents that automatically select a target mine.

Multimine dependencies

If you're running a Multimine project, the Scheduler Settings dialog will display an Inter Mine Dependencies panel in place of a Pushback Dependencies panel.

Where multiple mine operations are underway, it is common for mines to be mined consecutively or with a fixed time lag.

For example, mine B starts a few years before completing mine A, and ore will be crushed at one mine at a time (crusher will be moved from Mine A to Mine B). Any ore mined from Mine B while Mine A is in operation needs to be stockpiled.

The Inter Mine Dependencies panel allows you to define pushback dependencies between mines of a Multimine project. More...

Importing geological models into a Multimine project

You import block models into MMS documents in exactly same way as you import models into your project, except that you have to repeat the operation as many times as there are mines to be considered in the project. The number of mines must be at least two and the upper limit is set only by the available computing resources, especially RAM.

- The names of the mines are derived from the names of model files; the mines must have different names so you cannot import two files with identical names.

- If you plan to use MAO or MFO tools, you should be aware that the names of data fields representing mineral elements (products and attributes) in the geological models matter. MAO and MFO consider the elements coming from different mines and having identical names to represent the same mineral; for example, AU from Lonecone and AU from Malandani will be considered to be the same element while AU and Au will not.

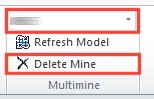

Deleting mines from a Multimine project

A mine can be deleted from a Multimine project at any stage of project development. To delete a mine, select its name in the Optimization ribbon's Multimine drop-down list, then select Delete Mine, immediately below (disabled for the [All Mines] option):

What happens when a mine is removed from a Multimine project:

- All data related to the mine are deleted from the document and from the disk. This includes the parcel model, the economic model, all mine specific surfaces, perimeters (traces), settings and report options.

- All Mines OES's are modified by removing the blocks from the deleted mines.

- Mine specific settings for the remaining mines are preserved (Economic Model, Pit Optimization and Pushbacks). Also, the All Mines Pit Optimization settings are preserved, except when the blending option is used.

- Scheduler and MAO/MFO settings are deleted as they no longer make sense and must be redone by the user.

- The reports are deleted. They can be recreated from the adjusted OES's without running the optimization modules again. Before recreating Scheduler and MAO/MFO reports, the user must redo the relevant settings.

- The Summaries are left unchanged, they can be redone by running the optimization modules.

|

|

IMPORTANT!The delete operation cannot be undone. It is recommended to backup the project before performing the operation. |

Generating economic models in a Multimine project

Each mine has its own economic parameters and its own economic model. You need to generate economic models for all mines before proceeding to the next optimization step. To achieve this, set the economic parameters for all mines, select [All Mines] at the Multimine toolbar list box and run the economic model generator.

If you plan to use MAO or MFO tools, note that processing plants defined for different mines and bearing the same name will be considered to be one plant shared by these mines.

Pit optimization in a Multimine project

MMS Pit Optimizer generates final pit shells separately for each mine and then proceeds to create an all mines extraction sequence in a way depending on the selected sequence option:

- NPV maximization option generates LG phases for each mine and goes on to make an all mines OES following the general rules where LG shell from a single mine is replaced by a collection of LG shells from all mines obtained for the same price (value) parameter.

- Blending generates all mines OES directly by extending the NPVS search process to all mines. If the search succeeds, the resulting collection of pits from all mines will represent the blended “pit”, while individual mines will not necessarily meet the blending targets on their own.

Prior to running Pit Optimizer, you must define all mine specific

settings as well as the “all mines” settings.

MMS Pushback Generator makes the pushbacks separately for each mine and then creates an all mines OES in the same way as Pit Optimizer creates an all mines OES from LG phases. Pushback Generator takes as input the all mines OES made by Pit Optimizer. Note that under the latter’s blending option this may lead to very different pushbacks than those generated by Studio NPVS for each mine separately.

Prior to runningPushback Generator, you must define all mine specific settings.

MMS generates an all mines schedule meeting all mines and mine specific targets. It works like NPV Scheduler but with more variables and more data. Note that the “sinking rate” limit can be set for “all mines” only. Scheduler generates an all mines OES as its output.

Prior to running Scheduler, you must define “all mines” settings and optionally, mine specific pushback dependencies and lags.

MMS MAO works like its Studio NPVS namesake. Note that rock types from different mines are always treated as separate variables while elements (products) and processes bearing the same name across all mines are treated as one variable.

MAO and MFO generate exportable “all mines” Result Parcel Models.

MMS MFO is an extension of MMS MAO in the same way as Studio NPVS MFO is an extension of Studio NPVS MAO. Note that the mine flow (cutoff grade) optimization is carried out for the “all mines” input produced by MMS Scheduler. The maximum mining rate variable refers to total mining rate for all mines. MFO generates another all mines OES as its output.

All capital costs are mine specific and are defined in the same way as in Studio NPVS whether as obstacle removal costs or as costs tied to pushbacks or time periods. The difference is that MMS includes capital costs from all mines in all mines optimization, scheduling and reporting.

All haulage destinations and their parameters are mine specific. MMS creates Meter Ktonnes (Foot Ktones) variables separately for each mine so you can set truck hours targets for individual mines or for all mines.

|

|

Related Topics |

|

|

Copyright © Datamine Corporate Limited

JMN 20065_01_EN